Industrial Edge Computing Revolution

Industrial automation technology is now widely used in production, control, and management processes, enhancing efficiency and scientific precision in operations.

Rockchip RK3588 / RK3568-Powered Controllers

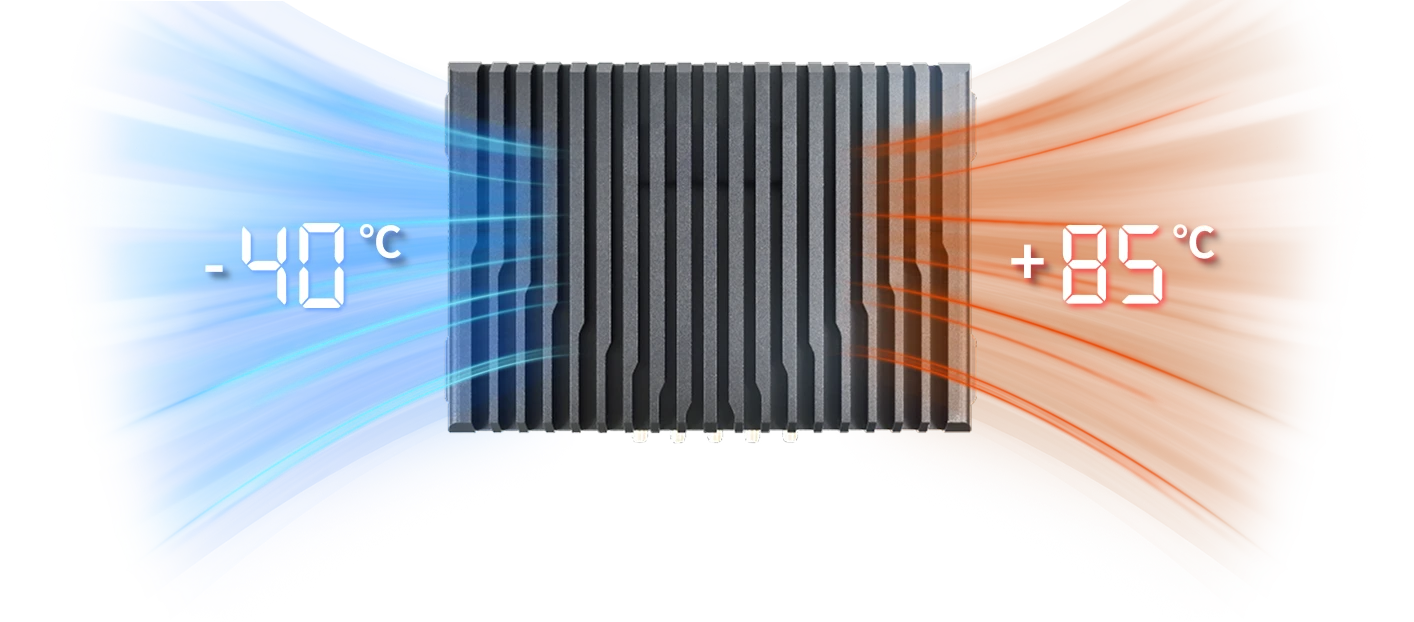

• -40°C to 85°C fanless operation

• Native industrial protocol support

• 65% lower TCO vs. traditional industrial PCs

Industrial Edge Computing Revolution

Industrial automation technology is now widely used in production, control, and management processes, enhancing efficiency and scientific precision in operations.

Rockchip RK3588 / RK3568-Powered Controllers

• -40°C to 85°C fanless operation

• Native industrial protocol support

• 65% lower TCO vs. traditional industrial PCs

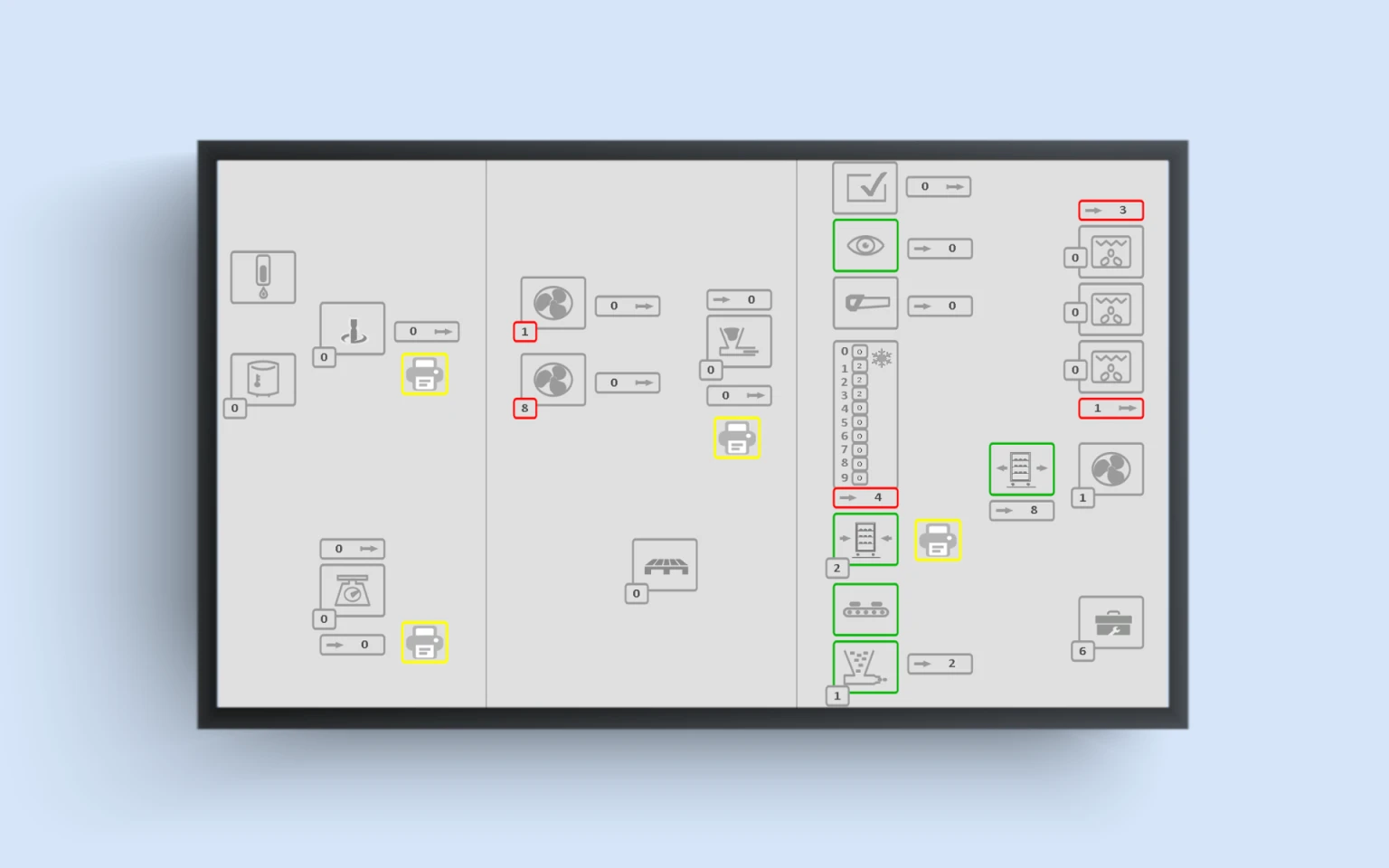

Bottlenecks Slowing Your Smart Factory Ambitions?

Traditional MES implementations often face critical bottlenecks that hinder efficiency and real-time decision-making

Protocol Chaos

PLCs, CNCs, robots, and sensors speak different languages (Profinet, Modbus TCP, EtherCAT, etc.), creating isolated data islands

Slow Response Times

The MES, designed for higher-level coordination, often operates on minute-level response times, unable to react to millisecond-level events on the shop floor

Data Overload & Latency

High-precision sensors generate massive time-series data. Transmitting everything raw to the cloud or central MES clogs networks, increases costs, and causes critical decision-making delays

Dirty & Harsh Environments

Standard computing hardware fails under extreme temperatures, dust, vibration, and electromagnetic interference

Space & Deployment Constraints

Control panels are crowded. Finding space for powerful computing nodes that also support flexible mounting (like DIN rail) is a common struggle

Your Intelligent Factory Hub

The RK3588 Edge Computing Industrial PC

The Compact, Rugged Edge Node for Seamless MES Integration

Built around the flagship Rockchip RK3588 processor, the RK3588 industrial min PC acts as a powerful neural hub at the edge, seamlessly integrating your equipment with your MES and solving these pain points definitively.

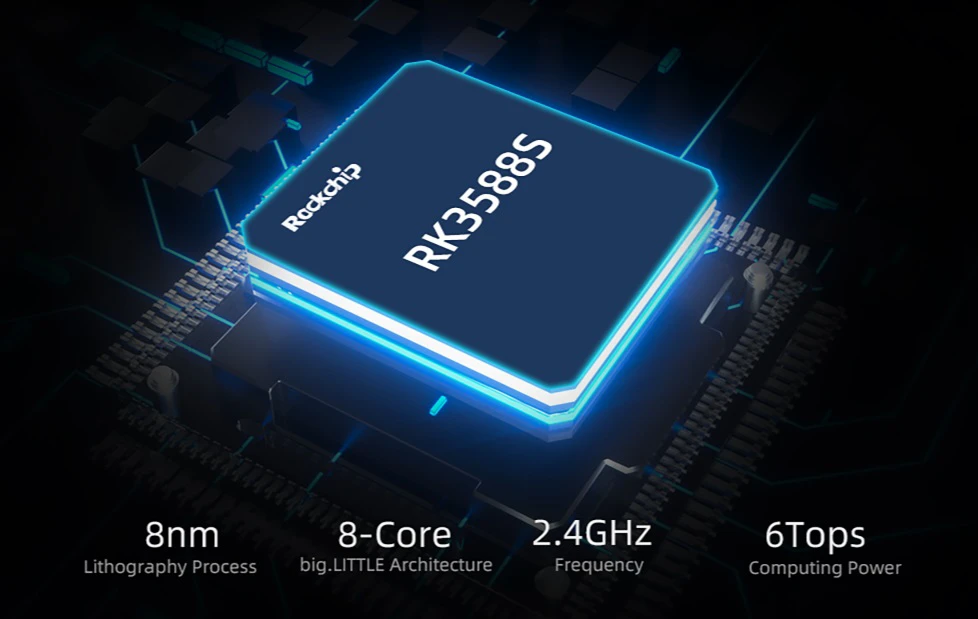

Why the RK3588 is a Game-Changer for Industrial Edge Computing?

Octa-Core Heterogeneous CPU

4x Cortex-A76 @ 2.4GHz + 4x Cortex-A55

Provides massive computing power for complex data processing, parallel protocol translation, and running lightweight applications directly at the edge.

6 TOPS NPU (Neural Processing Unit)

Enables real-time AI inference at the source—from visual quality inspection to predictive maintenance analytics—without sending data to the cloud.

Rich I/O Connectivity

Dual GbE, USB 3.1, Multiple Serial Ports, PCIe

Offers native support for connecting a vast array of industrial devices, sensors, and cameras. Easily expands with CAN bus, 4G/5G, or Wi-Fi 6 modules.

its rich I/O (multiple COM ports, Dual GbE) and powerful processing capabilities, it is the ideal hardware foundation for hosting any major protocol conversion software (e.g., Node-RED, Ignition Edge, or custom solutions).

8K Video Processing

Capable of handling multiple high-resolution camera feeds for advanced machine vision and monitoring tasks

Industrial-Grade Reliability

-40°C to 85°C+ operation, Fanless design

Built to thrive in harsh factory environments, ensuring continuous operation where commercial hardware would fail.

Key Features & Technical Strengths

|

Feature |

Key spec. |

Advantage |

|---|---|---|

|

Processing Power |

Robust RK SoC (or alternative like AMD Ryzen Embedded / Intel) |

Handles edge analytics, local database management, and simultaneous protocol translation smoothly. |

|

Connectivity & I/O |

Dual GbE LAN (or 2.5G), 4x USB, 4x RS-232/422/485 Serial Ports, optional WiFi 6/5G |

Connects to a vast array of industrial devices, sensors, and networks. Crucial for integrators. |

|

Expansion & Storage |

Multiple M.2 Slots (Key M & E) for NVMe SSD & wireless modules (LTE/5G, Wi-Fi) |

Future-proof flexibility for storage and communication upgrades without changing the core unit. |

|

Rugged Design |

Fanless cooling, wide voltage input (e.g., 9~36 VDC), wide operating temperature, DIN Rail Mounting |

Thrives in harsh electrical and physical environments, ensuring continuous operation. |

|

Security |

TPM2.0, Secure Boot, Hardware-based Encryption |

Protects your intellectual property and operational data from the edge into the network. |

How Our RK3588 Edge IPC Transforms Your MES Operations

Solve Protocol Silos & Unify Data

Pain Point: Incompatible machines and legacy equipment create data silos, making MES integration complex and costly.

Solution: Our RK3588 IPC provides the robust, open platform needed to break down these barriers. With its rich I/O (multiple COM ports, Dual GbE) and powerful processing capabilities, it is the ideal hardware foundation for hosting any major protocol conversion software (e.g., Node-RED, Ignition Edge, or custom solutions).

✅ Value: Accelerate your integration projects with a flexible and powerful hardware base.

Implement Smart Data Reduction & Preprocessing

Pain Point: Streaming massive, raw data from high-precision sensors and cameras overwhelms network bandwidth and clogs your MES database with irrelevant information.

Solution: Our RK3588 IPC provides the necessary processing power and tools to act as an intelligent data filter at the source. Instead of just passing through raw data, it gives you the platform to:

✅ Value: Turn data into actionable insights at the source.

Ensure Uninterrupted Operations with Edge Resilience

Pain Point: Network instability or outages can halt data collection and cripple production processes that are overly dependent on central systems.

Solution: Our IPC provides the critical edge resilience foundation to keep your operations running. We ensure the hardware and OS layer remains stable and provides key features:

✅ Value: Decouple production operations from network reliability.

Tangible Benefits for MES End-Users & Integrators

Beyond Specifications: Driving Real-World Value for Your Operations

For MES End-Users / Manufacturing Teams

For System Integrators

Tell us what you need

Trusted by 50+ Brands Worldwide | NDA Protection Guaranteed